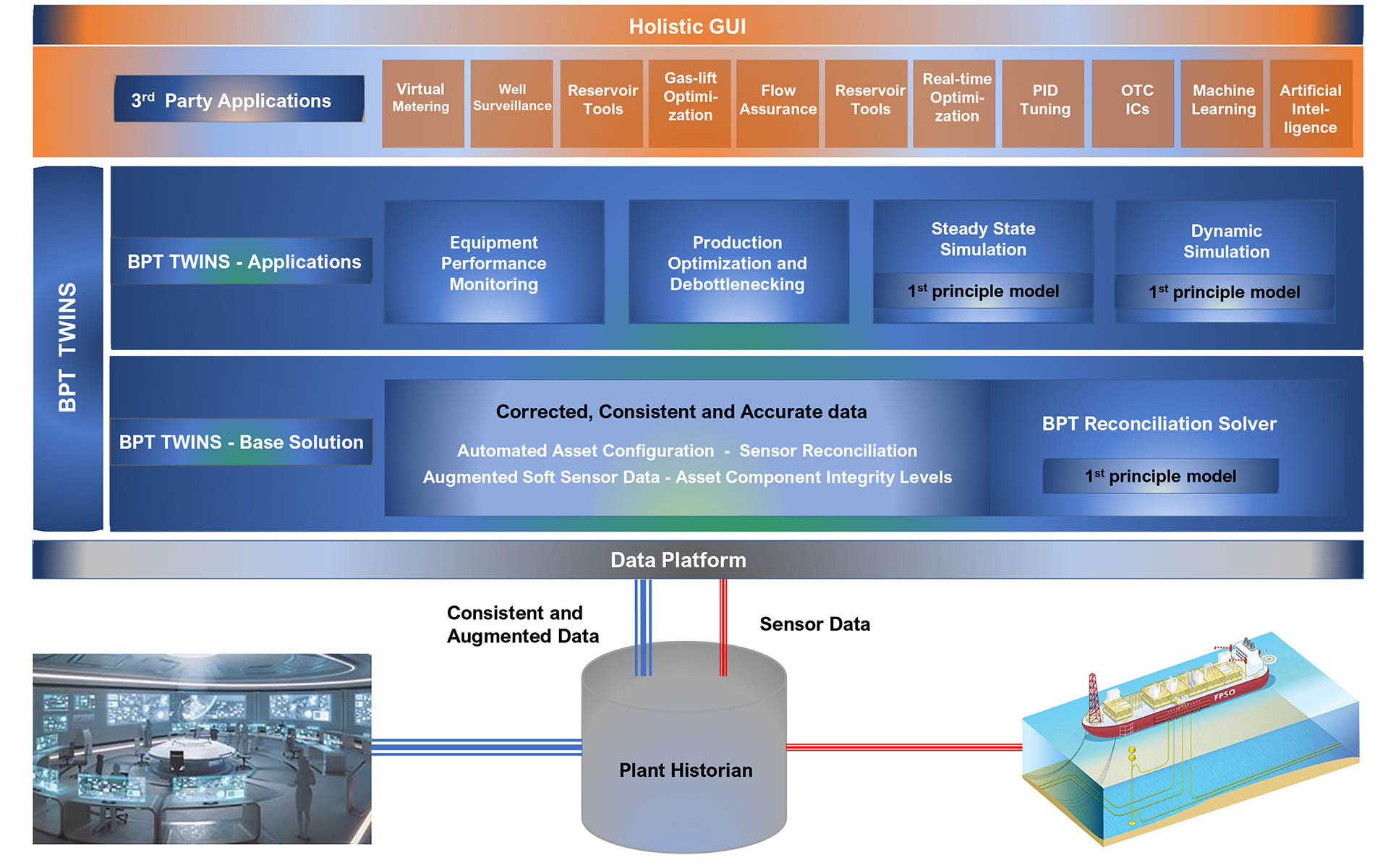

The BPT Digital Production Twins (formerly branded BPT DOSS - Digital Operator Support System) is a fundamental part of field development, lifecycle simulations, safeguarding sensor outputs, operational decision support, production optimization, safety, digitalization and data driven operations. BPT Twins is well proven and has been in operation since 2017. The solution is qualified as technology by major oil & gas company since 2019 and deployed in many operating oil & gas fields.

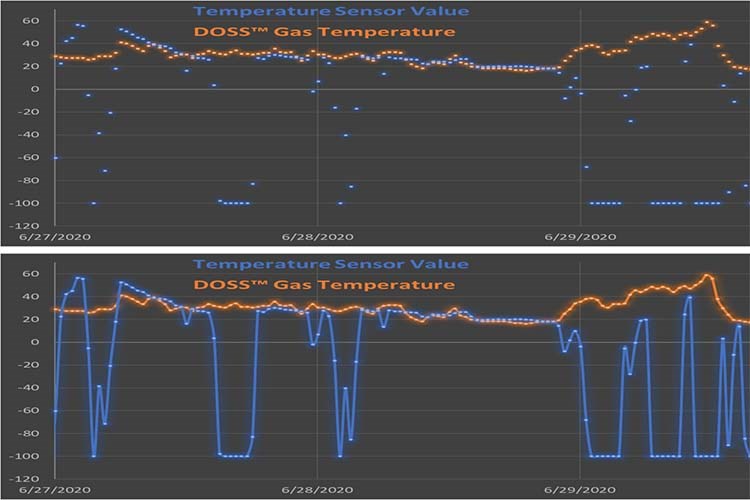

BPT Twins provides autonomous sensor data reconciliation using a 1st principle simulator tool to provide high quality, accurate and consistent data including full access to all augmented data. The digital solution automatically updating process models and asset integrity reports on a component level.

BPT Twins is an online digital replica of the assets/field production facilities. It easily integrates with other twins and enable other digital applications with quality assured data. BPT Twins provides invaluable insights for production, process and flow assurance engineers as well as instrument, automation, maintenance, safety and reservoir functions across the operational organization.

The BPT Twins solution is standardized and automated which facilitates fast deployment, in weeks rather than months. The solution typically covers the complete production facility, from wellbore and flowlines through topside or onshore processing facility to export, and the solution is designed for scalability and flexibility.

The BPT Twins solution is owned, developed, deployed and supported by BPT with our pool of domain and subject matter experts or deployed and supported in cooperation with one of our international integrator partners.

The BPT Digital Production Twin have been chosen by leading oil and gas companies.