Front-End Loading - the foundation for success

BPT’s domain experts are pioneers in applying FEL methodology and tools to discover & mitigate risks and enhance ROI at an early stage:

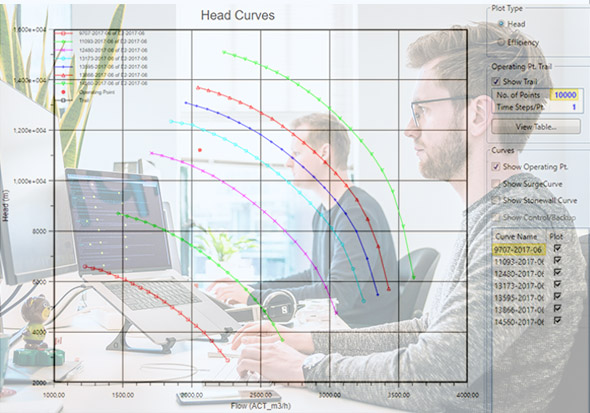

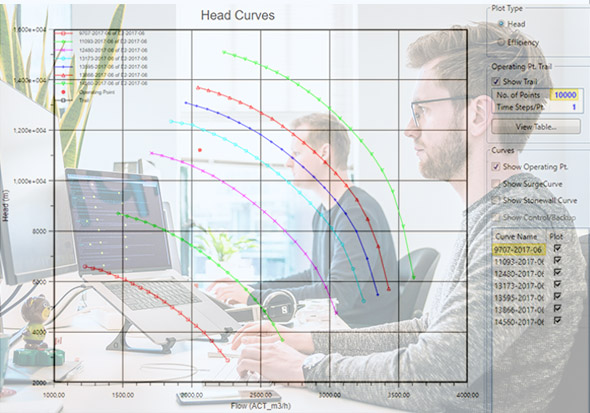

Efficient, innovative and state-of-the-art usage of simulation technology throughout all phases of field development, commissioning, startup and field life operations.

We improve process and system design for the complete field by much more detailed and wide analyses than during early stage of traditional field developments. Includes process optimization, compressor evaluations, design optimization and validation, process safety, process control and operational robustness.

We test control strategies towards the actual process models, including process control, process & emergency shutdown logic and compressor protection. Typical scenarios are start-up, shut-down and trips. Validation is done by simulation of control system in process simulator or integrating soft-controller with process model.

As an efficient way of improving performance and interoperability of integrated systems, we build virtual plant of the entire production facility from reservoir to export with control system as well as advanced control and all main digital applications in ecosystem for the specific field, hence total system performance could be fully validated much before field startup.

We provide high-fidelity operator training simulators for efficient training of central control room and field operators. Scope of simulator is typically the multiphase production system of wells, flowlines & risers and the entire processing facility integrated with control and safety systems as well as replica control system operator stations and instructor station forming a realistic training tool environment.

When the field goes live at first oil/gas, the production twin used under field development moves into an automated operational twin performing holistic sensor value correction with complete quality-checked datasets as output, providing calibrated steady state and dynamic simulator models for decision support and production optimization, as well as enabling innovation of other digital applications.

Read MoreDe-risk field developments, drive digital innovations and rise operational excellence!

BPT’s domain experts are pioneers in applying FEL methodology and tools to discover & mitigate risks and enhance ROI at an early stage: